3D Mold Scanning — A Revolution for Machinery Manufacturing

Exhaust pipe is a vital component for motor vehicles. Its main purposes are reducing vibration and noise, facilitating installation and lasting exhaust muffler system.

Although exhaust pipes are different in shapes, most of them have complicated structure, besides the welds are tiny and precise. Therefore, the processing precision for the inner cavity of exhaust pipe mold is extremely strict.

Nowadays, 3D scanning has already penetrated all aspect of automobile manufacturing. This innovative 3D technology can quickly and accurately obtain the full 3D data of the mold and then compare with the digital 3D model to calculate the deviations, which contributes to optimize and modify the product in further product development. While the traditional inspection methods are hard to achieve that.

What Mold Manufacturer Needs?

The mold manufacturer needs to get the complete 3D data of the exhaust pipe’s low die and obtain the deviations by comparing with 3D model so as to know whether the three exhaust pipes on datum plane are vertical to cylinders. However, the traditional inspection methods like CMM can’t capture comprehensive 3D data and time-consuming. Hence, an efficient 3D inspection is of great significance for the mold manufacturing industry.

ScanTech 3D Solution

Detecting plane and cylinder, we decide to use HSCAN handheld 3D laser scanner to scan the spatial positioning points and get 3D shape of the mold. The 3D data will be transmitted into the 3D software ScanViwer and aligned with the design drawings to generate the inspection report.

Scanning Process

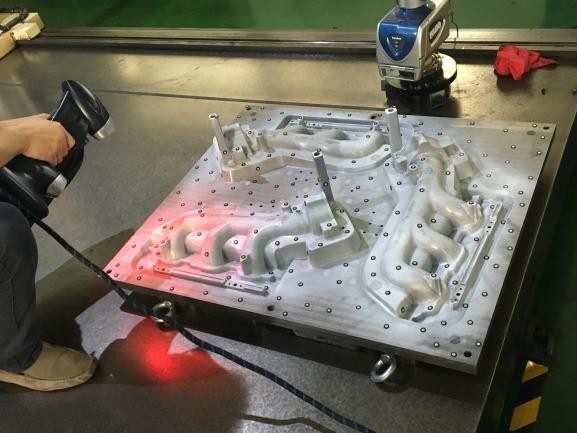

Step 1: quickly attach markers without spraying powder

Step 2: 3D scanning of exhaust pipe mold by HSCAN 3D scanner

Step 3: get accurate 3D data

3D data of exhaust pipe mold

Original mold

Step 4: comparison between 3D data and 3D model to get correct deviation values

Color Map

Color Map

By using HSCAN handheld 3D laser scanner, the ultra-high details of exhaust pipe mold are easily captured in a very short time. The flexible 3D scanning drastically cuts down the work time and facilitates product optimization. The scanning results intuitively reflect the deviation values, which brings great convenience for mold inspection and further modification in automobile manufacturing.

For more case about mold inspection, please read below:

Color Map

Color Map