All About the STL Format

Currently, desktop 3D printers primarily recognize 3D model files in the STL format. 3D modelling software such as 3DMAX, Maya, AutoCAD, and Solidworks can export files in this format.

Once an STL file is imported into Cura, it can generate code, the executable code for 3D printers, enabling the 3D printing process.

What is an STL File?

STL stands for stereolithography. It is an interchangeable file format used to represent three-dimensional surface geometries. This format is widely utilized in rapid prototyping, 3D printing, and computer-aided manufacturing (CAM).

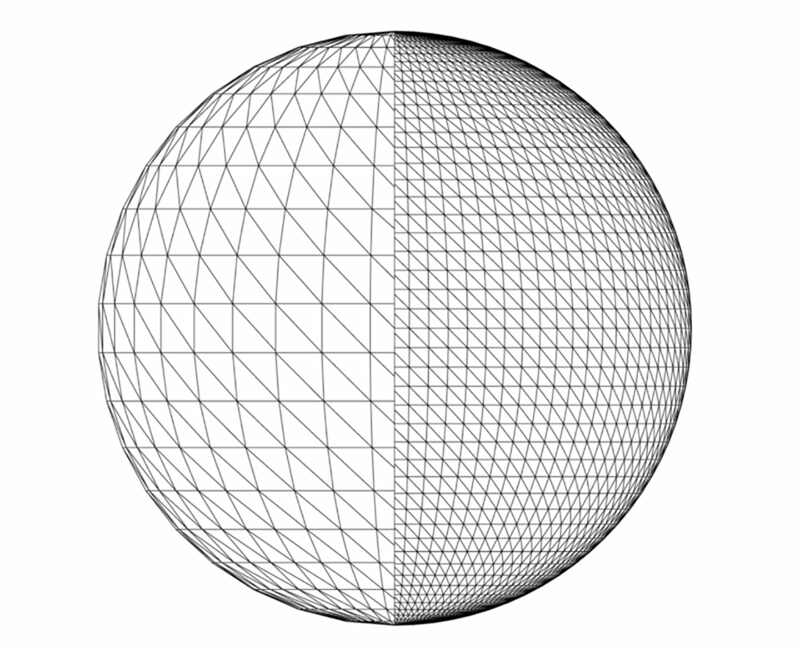

STL files represent surfaces as a series of small triangles, known as facets, where each facet is described by a normal direction and three points representing the vertices of the triangle.

Applications use this data to determine the cross-sections needed to construct the 3D shape. STL files do not contain information about colors, textures, or other common CAD model attributes.

These files are typically generated by computer-aided design (CAD) programs as the final product of the 3D modelling process. “STL” is the file extension for the STL file format.

Invented by 3D Systems, the STL format is the standard triangulated language for 3D printers, and all forming machines can process STL files for printing.

How do STL Files Work?

The basic concept involves subdividing the two-dimensional outer surface of a 3D model into small triangles, or facets, and storing the information about these facets in the file.

For instance, a simple 3D cube can be covered by 12 triangles, with each face consisting of two triangles. Since a cube has six faces, a total of 12 triangles are used. A 3D model of a sphere can be covered by many small triangles.

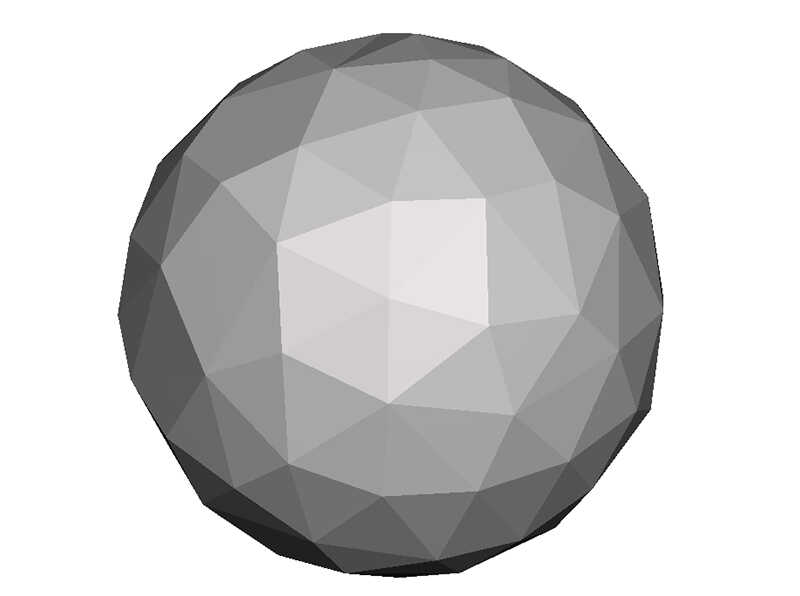

The STL file format approximates the surface of a CAD model using these small triangles. This approximation is never perfect, and the facets introduce a degree of roughness to the model.

Accuracy Issues with STL Files

When saving an STL file, all designed surfaces and curves are converted into a mesh composed of a series of triangles, representing the geometric meaning of the design prototype.

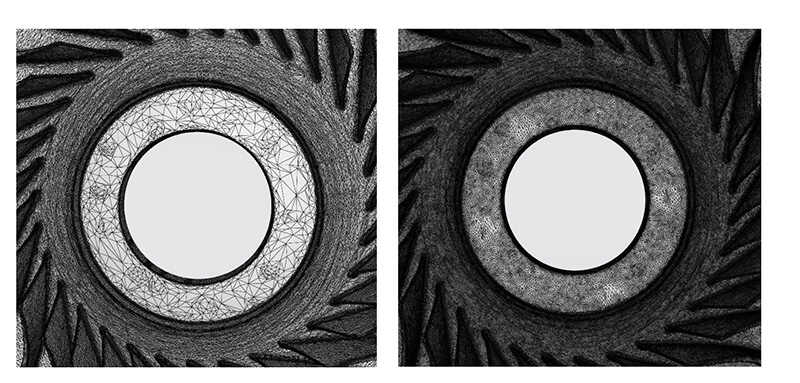

An STL file consists of numerous triangular facets that approximate the target curves and surfaces.

Due to the nature of this approximation, there will always be some error. The more triangles used, the closer the approximation to the true value, but this also makes the file significantly larger and harder to process.

Conversely, using too few triangles can result in low accuracy and large errors. Therefore, an STL file needs to have an appropriate level of accuracy. Typically, keeping the accuracy within 0.05 is suitable.

If an STL file is too large, Cura may not be able to process it. This is often due to an excessive number of facets. In such cases, the file can be simplified by reducing the number of facets.

Since the physical printing process has its own precision limits, having too many or too few facets is not ideal. Finding a balance between file size and print quality is crucial.

Issues with Exporting STL Files

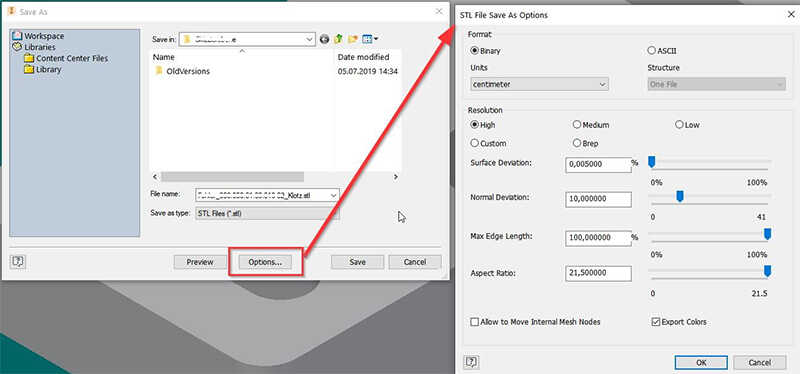

When exporting STL files, most CAD software provides settings that control the size of the facets, which in turn control the print quality and file size.

The accuracy of the exported STL model is directly related to the size of the triangular facets.

Smaller and more numerous facets result in a model that is closer to the original CAD surface. When dealing with complex surfaces, low export accuracy can cause significant deviations in the model, leading to errors and defects.

Therefore, it is advisable to maximize accuracy when exporting STL files, and overly dense triangular facets can be simplified using software like Magics.

CAD models created through solid modelling generally result in fewer errors when exported as STL files, whereas surface modelling can lead to various issues.

Prioritize solid modelling during the design phase, or convert surface models to solids. Perform Boolean operations before exporting solids to minimize the need for model repair.

Sometimes, errors are reported when exporting STL files. These errors are not generated during the export phase but actually exist in the file’s object.

Like how software compilers check for programming errors, 3D printers or STL viewers check STL files for errors. If the machine encounters a problematic file during model construction, it will crash and stop, leading to print failure.

Converting to STL Format in 3D Software

3ds Max

● Select the model.

● Go to File > Export > Select STL format.

● Click OK.

AutoCAD

● Ensure the design is a 3D solid and all coordinates are positive.

● Enter “FACETRES” in the command line and input a number between 1 and 10 (1 for low resolution, 10 for high resolution).

● Enter “STLOUT” in the command line and select the target model.

● Enter “Y” to output binary and save the file with a name.

Autodesk Inventor

● Select File.

● Send to 3D Print Service.

● Choose Export File Type: STL Files.

● Click OK.

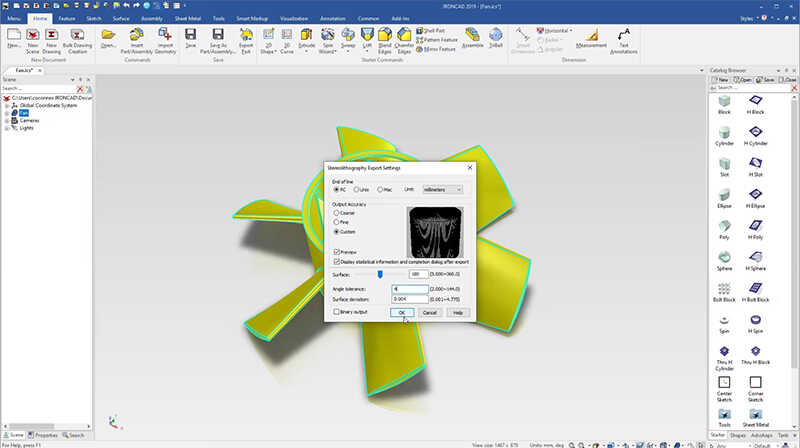

IronCAD

● Right-click on the part to be exported.

● Go to Part Properties > Rendering.

● Set Facet Surface Smoothing to 150.

● Go to File > Export.

● Choose STL format.

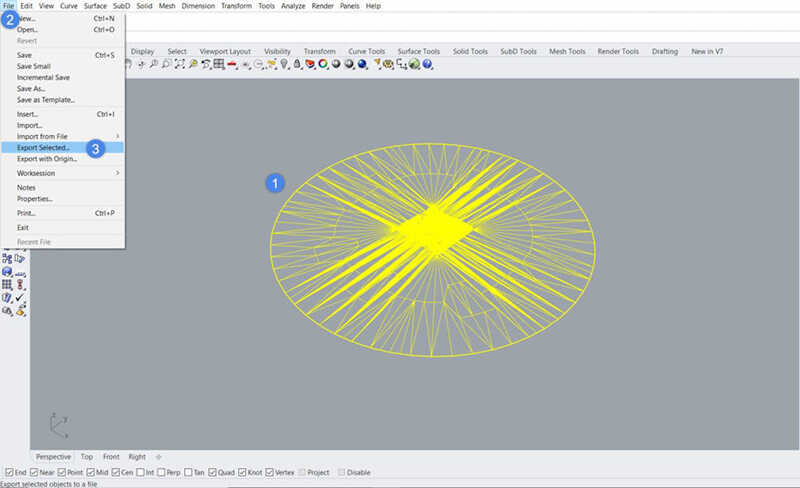

Rhino

● Go to File > Save As and select File Type > STL.

● Enter the STL file name.

● Click Save.

● Choose Binary STL Files.

Compare Products

Compare Products

All Products

All Products